About Bayside Laser

Wiki Article

A Biased View of Bayside Laser

Table of ContentsThe Greatest Guide To Bayside LaserSome Known Facts About Bayside Laser.Bayside Laser Things To Know Before You BuyBayside Laser Can Be Fun For EveryoneSome Ideas on Bayside Laser You Should KnowSome Ideas on Bayside Laser You Should Know

Flying optic devices have to use some technique to take into consideration the altering light beam size from the near field (near the resonator) cutting to the far field (away from the resonator) cutting. Common techniques for regulating this include collimation, flexible optics, or using a continuous beam length axis.

The power usage and performance of any type of certain laser will differ depending upon output power as well as running specifications. This will certainly depend on the sort of laser and also exactly how well the laser is matched to the operate at hand. The amount of laser cutting power called for, known as warm input, for a certain task relies on the material type, density, procedure (reactive/inert) utilized, and also wanted cutting rate.

Bayside Laser for Dummies

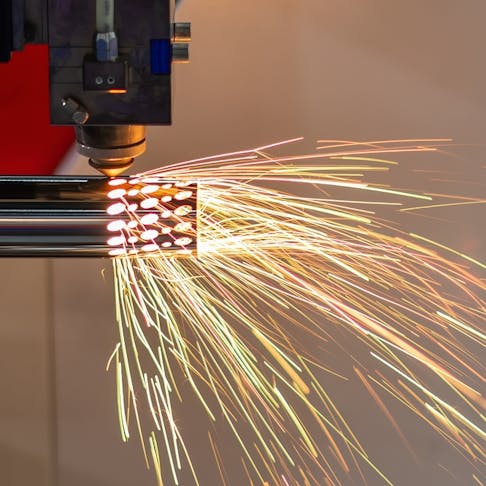

Utilizing computerised systems enables specific and also intricate forms that would certainly have been difficult with typical cutting (metal laser cutting). The individual can quickly control the cut's depth by adjusting the laser beam's power and also emphasis. Laser cutting is typical in steel, timber, plastics and also textiles. It additionally has applications for inscribing, engraving and also noting.Whether you're trying to find a new or updating your procedures, laser cutting has vast applications, particularly in manufacturing. That claimed, right here are four benefits of laser cutting: Laser reducing is among the most innovative, exact as well as accurate approaches for reducing materials. It can provide a degree of detail and also precision that hand tools can never ever get to.

Getting My Bayside Laser To Work

The capacity for laser cutting appears practically infinite as it supplies services top quality standard results in a fraction of the moment. Laser-cutting technology is flexible and suitable with various products, varying from wood and also leather to even more difficult-to-cut metals. For these harder-to-cut products, laser cutters create best precision cuts that are not available with standard cutting devices.Laser-cutting devices are as straightforward as a lot of equipment goes. Still, below are four tips to aid get the most out of your process: With laser cutting, choosing the suitable product for the work is vital. Relying on the desired application, different materials may be better than others relying on aspects such as toughness as well as safety and security.

Not known Facts About Bayside Laser

Clearly, laser cutting is a whole lot faster than the conventional technique of reducing steel, yet is it much faster than various other modern methods? Laser cutting beats thermal reducing approaches such as plasma or fire in rate when reducing steel of up to 10mm thick.For those that require to cut great deals of different shapes, laser cutting is most definitely one of the most appealing metal reducing alternative. With this technique of reducing steel, you do not require to change devices to make various cuts as the exact very same configuration will certainly perform multiple reducing jobs as long as the density remains the very same.

During the laser reducing process, the light beam used does not in fact need to touch the product that is being cut, leading to less danger of damages. This implies that you will certainly not need to sustain costly fixings or delayed conclusion times as you might with various other methods of reducing steel - cnc cutting service.

The Ultimate Guide To Bayside Laser

look these up Laser cutting requires less power than other techniques, making use of on average 10k, W of power compared to 50k, W for other reducing procedures. Of training course, the safety of your workers is constantly at the center of your mind and also laser cutting supplies among the most safe ways of cutting metal.That specific factor develops a super high intensity that can puncture the product. The whole procedure is regulated by, you presumed it, a computer. Behind that computer system is commonly a qualified professional that assists assist the procedure so whatever runs smoothly. Compared to traditional reducing approaches, laser cutting offers several benefits.

Unlike numerous producing machines, laser cutters generally do not need you to switch over out various tools for whatever cut you want (https://linktr.ee/ba7sid3laser). The nice aspect of laser reducing devices is that they can work within the very same arrangement while providing various reducing alternatives. Laser cuttings use extreme precision contrasted to other typical reducing techniques.

Examine This Report about Bayside Laser

Relying on how a laser cutter is established up, you're frequently going to observe perhaps a tiny burr on a part. Generally, it's not required to get rid of the burr, yet it depends upon the material, its density and other elements. Oh yes, this is just one of the very best parts of utilizing a laser cutter; convenience.

No job is as well made complex for the laser cutter. A really slim area of material is easily navigated by the high-powered laser as well as is extremely hardly ever deformed or altered. Tasks are not simply limited to sheet metal with a laser cutter. Lasers have the ability to cut stainless steel, aluminum, copper, as well as brass.

Report this wiki page